Please can you tell me your application of PVA?

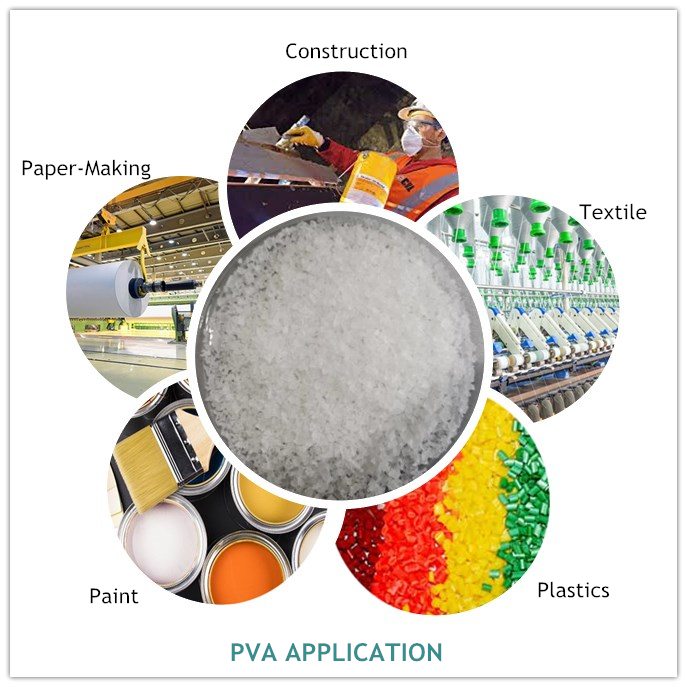

Polyvinyl alcohol (PVA) is a versatile polymer with various applications. It is commonly used in the following fields:

In the textile industry, PVA is employed as a sizing agent to enhance the strength and smoothness of yarns.

In adhesives, PVA provides strong bonding properties and is found in many woodworking and paper gluing applications.

It is also utilized in the production of films for packaging due to its good barrier properties.

In the medical field, PVA is used in the manufacture of certain types of medical dressings and drug delivery systems.

Furthermore, PVA plays a role in the construction industry as a component in some adhesives and coatings.

Textile industry:

Application: As a yarn slurry, it increases the strength and gloss of the fiber.

Recommended addition amount: The concentration of the slurry is usually between 6-15%.

Papermaking industry:

Application: Used as a reinforcing agent for paper to improve the strength and tear resistance of paper.

Recommended addition amount: Add 0.5-2% PVA to the pulp.

Adhesive industry:

Application: Used to make wood adhesives, paper adhesives and packaging material adhesives.

Recommended addition amount: Adjusted according to the specific adhesive formula, the concentration is usually between 10-30%.

Construction industry:

Application: Used as a reinforcing agent for tile adhesives, plasters and mortars.

Recommended addition amount: Add 0.1-2% PVA to mortar.

Pharmaceutical and cosmetic industry:

Application: Used in the coating of tablets, or as a moisturizer for cosmetics.

Recommended addition amount: Usually between 0.1-5%.

At Rixu Group, we value the relationships we build with each of our clients. When you choose us for your PVA needs, you’re not just buying a product; you’re joining a family dedicated to support and understanding. Our clients, from places like the Middle East, South America, and Southeast Asia, prefer using letters of credit for payment, whether you know why?

Recently, a kind client from Algeria became part of our family. After receiving a simple sample, he confidently placed an order of 19 tons of PVA 2688. We wish him great success in his business and happiness for his family, showing our commitment to not just business growth but personal well-being.

At Rixu Group, a deal is more than a sale—it’s the start of a lifelong friendship. We invite you to join a community where everyone is important, every effort is recognized, and every success is celebrated together.

Polyvinyl alcohol (PVA) is made from vinyl acetate through polymerization and alcoholysis. It is a white, stable, non-toxic water-soluble polymer in the form of powder, flake or flocculent solid.

Polyvinyl alcohol contains many alcohol groups, is polar, and can form hydrogen bonds with water, so it can dissolve in polar water; it can also dissolve in hot hydroxyl-containing solvents such as glycerol and phenol, but is insoluble in general organic solvents such as methanol, benzene, acetone, and gasoline.

1. If used to prepare water-soluble glue, PVA with medium polymerization degree and high alcoholysis degree is usually selected, which can ensure good water solubility and suitable viscosity.

2. In the field of textile slurry, it may be necessary to select PVA of different specifications according to different textile processes and fiber materials.

3. For some applications with high requirements for water resistance, such as waterproof coatings, PVA with low alcoholysis degree may need to be selected.

1. Fluctuations in the price of raw materials (such as ethylene, vinyl acetate, etc.),

2. Complexity of the production process,

3. Market supply and demand

We supply any quantity, no MOQ, for PVA, different quantity different price due to it is tax refund product.

PVA should be stored in a dry, ventilated, and cool warehouse away from fire and heat sources. Avoid contact with chemicals such as acids and alkalis to prevent chemical reactions. The packaging should be kept intact during storage to prevent moisture absorption and contamination.

Whether it’s a quick inquiry or a detailed discussion, we’re here to provide the support and information you need. Your success is our priority, and we’re just a message or call away. Contact us with confidence—your queries are welcomed anytime.

One-station For China Chemical Raw Materials

WhatsApp us for more